Cookies

This site uses cookies to provide essential functionality and to improve your experience. Please confirm you are happy to accept cookies in order to use the website.

Tamlite Lighting Ltd are a UK based Company, manufacturing domestic and commercial light fittings. Their parts are manufactured completely in house utilising thin sheet metal steel, of which is formed and finally powder coated to be further processes into domestic and commercial light fittings of very high quality.

Through continuous success and growth they have increased output to a point where they ran a three shift system to satisfy demand. Tamlite Ltd. decided to invest in their process to increase production capacity with a view to reducing the shift pattern and working hours. FIT Infrared (EU) Ltd. were approached to provide a curing system for the powder coated parts, this was to be installed integral with a new automated powder coating facility and conveyor.

Tamlite Lighting identified a target capacity of 105,000 units per year on a two shift bases, this was to provide an increase of 62% and a reduction in operating hours of 33%. The project objective was to install all facilities with minimum disruption to their existing production.

The oven capacity allowed the working hours to be reduced to a two shift system and also allowed production to increase by 40,000 units per year. The new FIT Infrared gas catalytic oven reduced the cost per part from original of £0.31 to £0.093 saving £0.217 per part (70% reduction in energy cost).

Working closely with the customer and the other contractors, a project plan was agreed which created minimum effect and risk to existing production and allowed the project to be completed in a safe and timely manner.

FIT Infrared (EU) Ltd. manufactured the oven to the agreed design, and installed it based on the agreed project timing plan.

Daily project meeting were held with the customer to discuss progress and sign off key stages.

Following installation, the ovens were commissioned and various light unit sizes cured to provide the ideal curing cycle. Training was carried out for maintenance and operators.

All commissioning data was compiled within the technical file to ensure any variation or changes to the process over time would be easily identified and addressed.

A service agreement was drawn up to ensure the oven continuously runs to optimum levels.

The existing oven was the main bottleneck and was proving un-reliable and inconstant. The oven was the highest cost contributor in the manufacture with an annual gas usage of 669,700 kW of Natural gas at a cost of £20,091 and a cost per part of £0.31.

The existing oven produced 127 tonnes of CO2 / 34.69 tonnes of Carbon per year.

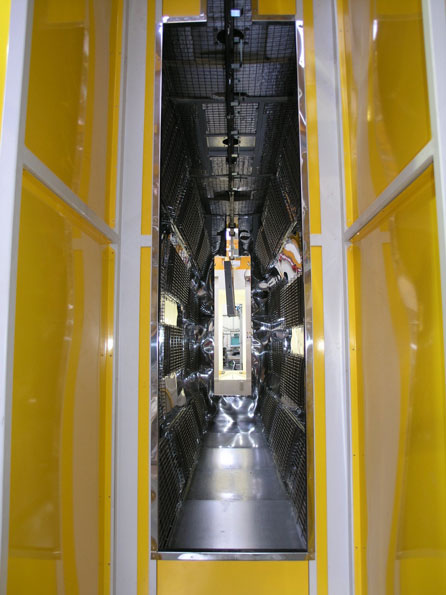

FIT Infrared (EU) Ltd. carried out on site trials to identify ideal cure time, in conjunction with the target line speed we designed an oven to satisfy the objectives. The new oven utilised gas catalytic heaters of gas usage 325,800 kW per year. The oven design allowed the side walls to be moved in and out providing process flexibility creating the ideal heat and curing profile to suit the size of the product, in addition a facility was installed allowing the operator to vary the gas pressure and subsequent heat intensity, this allowed the operators to set the oven to its optimum running level.

Based on target production of 105,000 units per year on a two shift basis

| Actual production output per year | 105,300 (two shifts) |

|---|---|

| Annual reduction in Co2 | 65.1 tonnes (51%) |

| Energy cost saving per unit | £0.217 (70%) |

| Projected annual energy cost saving | £22,785 |

| Annual capacity increase (two shifts) | 40,300 (62%) |

| Weekly working hours reduction | 30 hours |